Key Features:

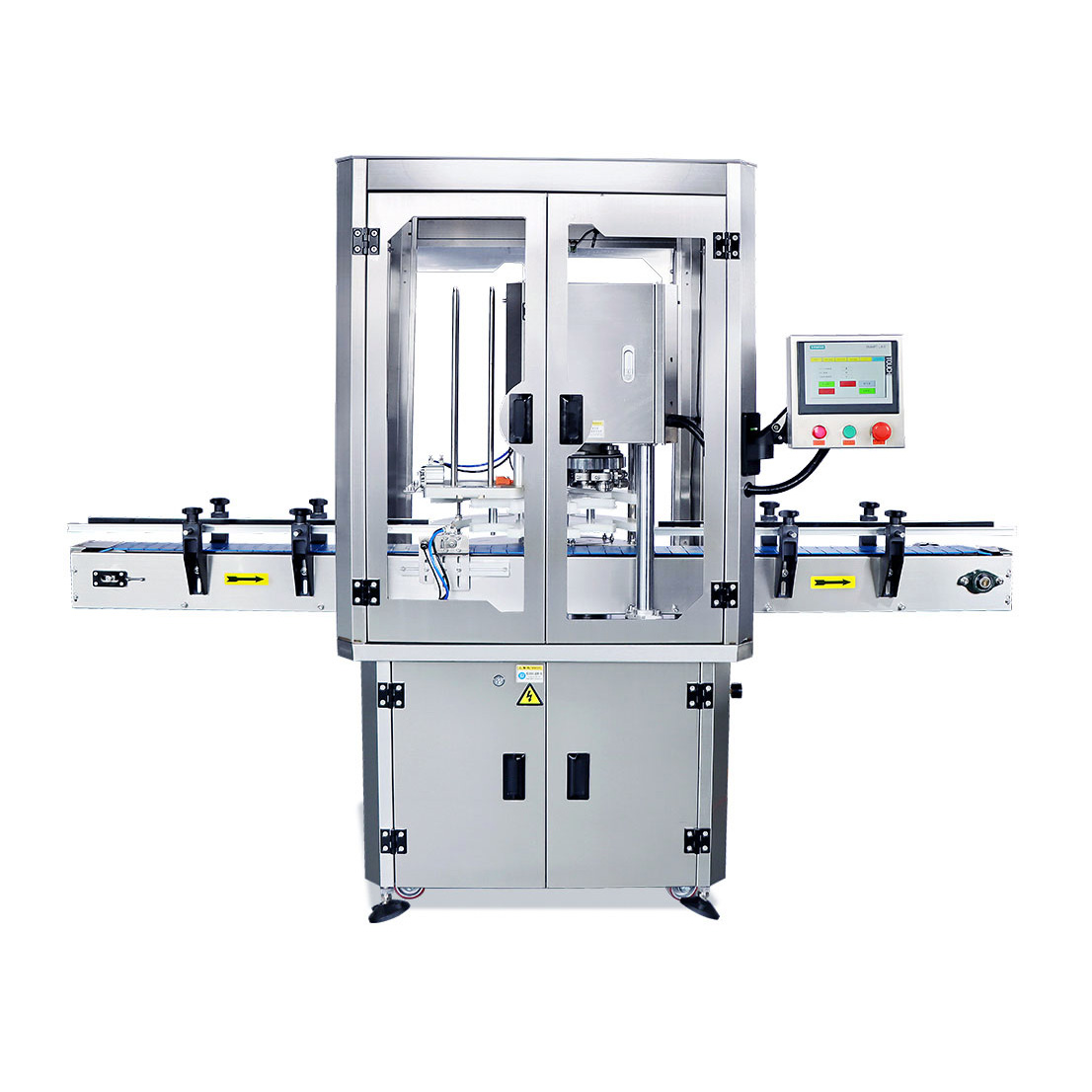

- Servo-Controlled Operation: The machine utilizes a servo control system, ensuring safer, more stable, and intelligent performance. The turntable activates only when a can is detected, with adjustable speed settings. In cases of deformed cans or foreign objects, the turntable automatically halts to prevent damage and ensure operator safety. A one-click reset function allows for quick troubleshooting, minimizing downtime and enhancing production efficiency.

- High-Efficiency Sealing: Equipped with a single sealing head comprising four rollers (two for first sealing, two for second sealing), the machine ensures high sealing integrity. The rollers, made from high-hardness, high-finish materials, guarantee smooth, compact, and leak-proof seals, with a lifespan of up to 10 million cans.

- Advanced Control Systems: Incorporating the internationally renowned Siemens PLC control system and German SICK sensor technology, the machine maintains stable sealing and filling accuracy throughout production, ensuring consistent product quality and operational safety.

- Versatility: Designed to accommodate cans of various specifications, shapes, and materials, the machine meets diverse production needs while reducing operational costs. Notably, the can body remains stationary during sealing, making the process safer and suitable for fragile or liquid products.

- High Automation: Features such as automatic lid placement and sealing significantly boost production efficiency and lower operating costs.

- User-Friendly Design: The machine boasts a simple mechanical structure, facilitating easy operation and maintenance. Low maintenance costs and straightforward repairs help minimize production losses due to downtime.

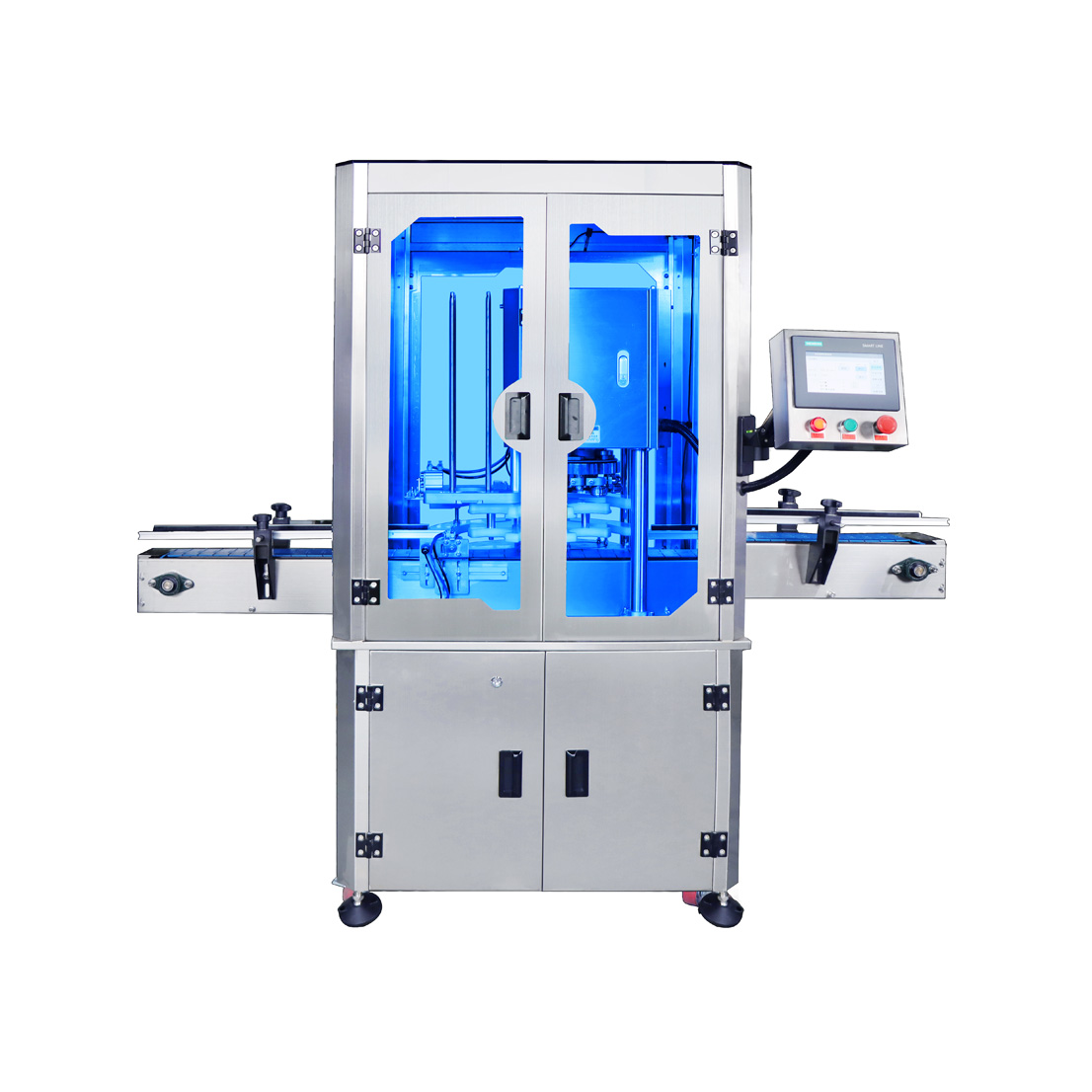

- Enhanced Safety: A blue acrylic outer cover provides double safety protection. The machine stops operation when the door is opened or when a bottle is blocked, ensuring user safety and a more humane design.

Technical Specifications:

- Sealing Head: 1 head with 4 rollers (2 for first sealing, 2 for second sealing)

- Sealing Speed: 20-55 cans per minute (adjustable, depending on can material, size, and contents)

- Sealing Height: 25-220mm (additional molds required for larger heights)

- Sealing Diameter: 30-110mm (8 stations), 60-160mm (6 stations)

- Air Consumption: 150L/min

- Power Supply: Single-phase AC220V 50/60Hz

- Total Power: 1.7KW

- Net Weight: Approximately 330kg; Gross Weight: Approximately 400kg

- Conveyor Belt Height: 850mm

- Main Material: 304# stainless steel

- Dimensions: Approximately 2430mm (L) x 848mm (W) x 1800mm (H)