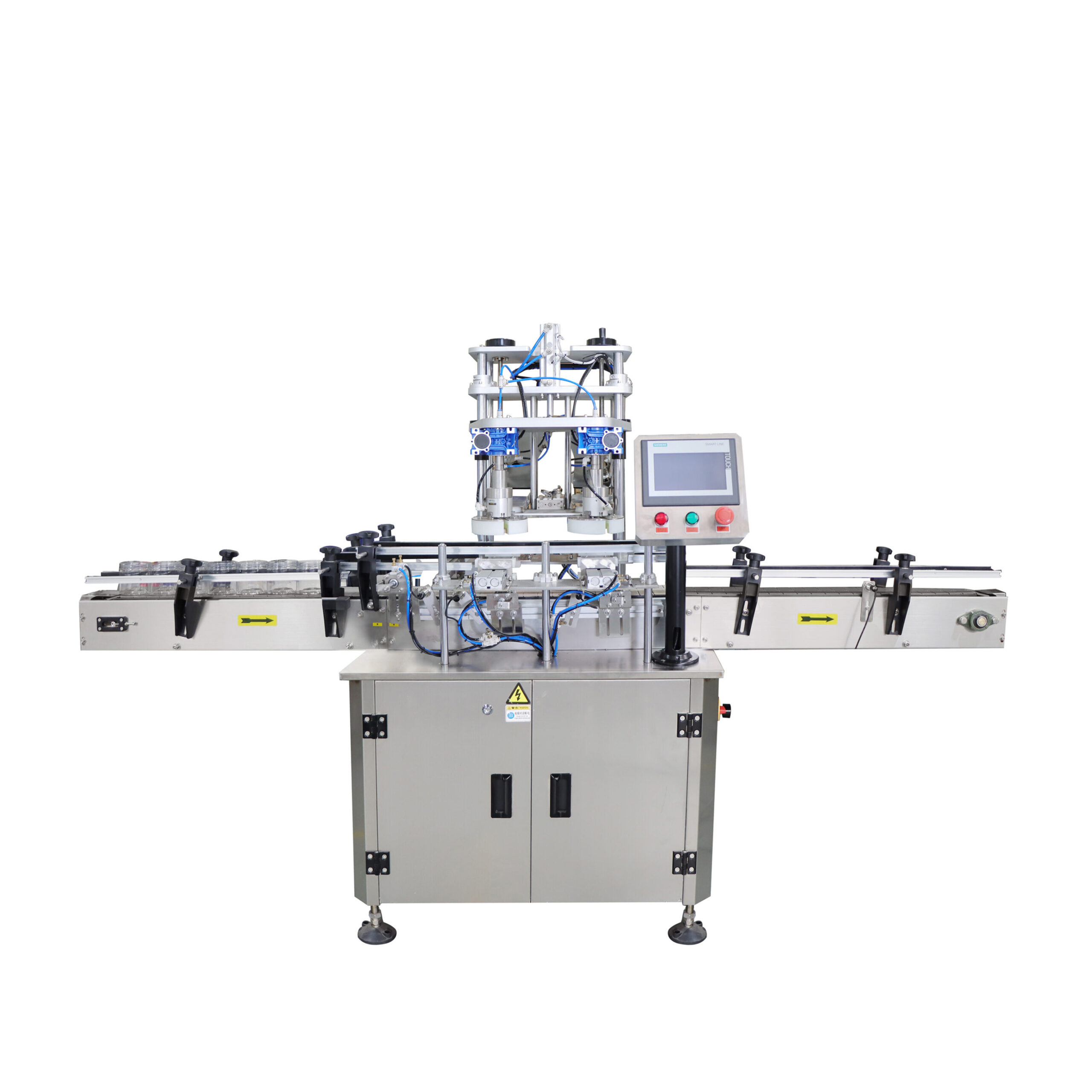

Key Features:

- Servo-Controlled Precision: Equipped with a servo-driven system, this machine ensures adjustable and controllable torque, delivering accurate and consistent capping results.

- Gentle Cap Handling: The machine mimics human hand movements to grasp caps in parallel, preventing damage by avoiding jamming or over-tightening, thus maintaining cap integrity.

- Quick Mold Changeover: Designed for versatility, it allows for rapid mold changes within one minute, accommodating various bottle sizes and reducing downtime.

- Advanced Control Systems: Incorporating internationally renowned Siemens PLC control systems and German Sick sensor technology, the machine ensures stable operation and ultra-high-precision capping, achieving an accuracy rate of up to 99.99%.

- High Versatility: Capable of adapting to bottles of different specifications, shapes, and materials, it meets diverse production needs while minimizing operational costs.

- Automation and Efficiency: Featuring automatic cap feeding and screwing, the machine significantly enhances production efficiency and reduces operating costs.

- Low Maintenance: With a simple mechanical structure, the equipment is easy to operate and maintain, lowering production losses due to downtime.

Technical Specifications:

- Cap Feeding Method: Air gripper for stable and reliable cap placement.

- Cap Sorting Method: Lifting and sorting caps with replaceable guide rails and components for different cap types.

- Cap Feeding Speed: 600 to 9,600 pieces per hour.

- Capping Method: Servo torque-limited gripping capping.

- Capping Speed: 1,500 to 2,500 bottles per hour.

- Total Power: 1.4 kW.

- Power Supply: AC 220V, 50/60Hz.

- Working Air Pressure: 0.5 to 0.6 MPa.

- Air Consumption: 170 L/min.

- Applicable Range: Cap diameters from 20 to 120 mm; bottle heights from 30 to 250 mm.

- Conveyor Belt Height: 850 mm.

- Main Material: 304# stainless steel.

- Dimensions: Approximately 2,424 mm (L) x 1,842 mm (W) x 2,190 mm (H).