Canning line equipment refers to a comprehensive suite of machinery and systems designed for the industrial process of canning, which involves filling, sealing, and processing food, beverages, or other products in metal or composite cans. This category is pivotal for food and beverage manufacturers looking to preserve quality, extend shelf life, and ensure product safety. Here's an overview of key components and functionalities within this category:

- Can Depalletizer: Automated machines that remove cans from pallets, preparing them for cleaning and filling. These can be semi-automatic or fully automated, handling different can sizes and stack configurations.

- Can Washer: Ensures that cans are clean before filling, crucial for maintaining hygiene standards. These machines use water, steam, or chemicals to clean both the interior and exterior of cans.

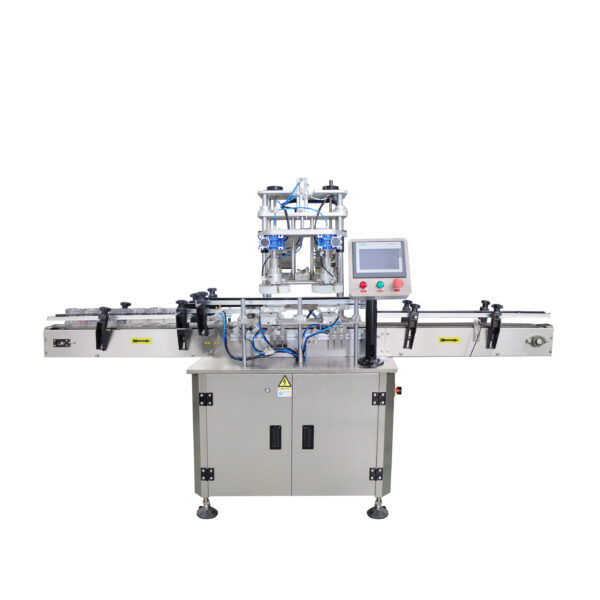

- Filler Machines: Tailored to the product, fillers can range from gravity fillers for liquids, to vacuum fillers for viscous products, or even pressure fillers for carbonated drinks. Precision in fill levels is critical for both product quality and can integrity.

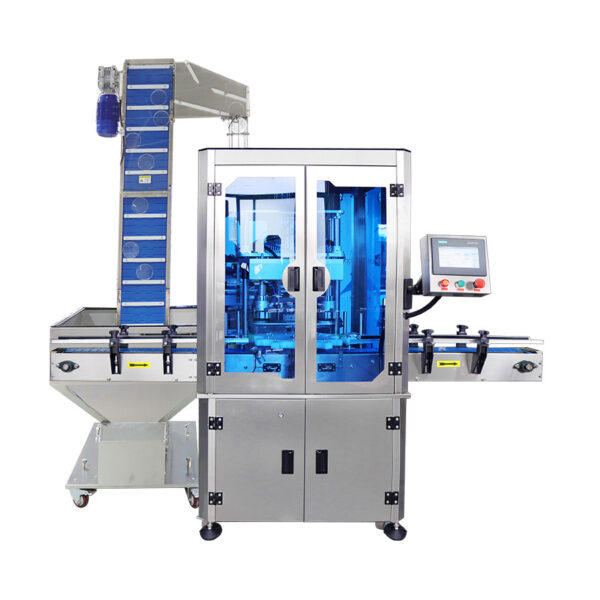

- Seaming Machines: After filling, cans must be sealed to prevent contamination and preserve contents. Seaming machines (or closers) crimp the lid onto the can, ensuring an airtight seal. They vary from single-head for small batches to multiple-head for high-speed production lines.

- Pasteurizers or Retorts: Depending on the product, cans might need to go through pasteurization or retort processing to kill off bacteria and extend shelf life. Tunnel pasteurizers use hot water or steam, while retorts are used for products needing high-pressure processing.

- Cooling Systems: Post-processing, cans often need to be cooled down to stop the cooking process, ensuring the product does not overcook or spoil. Cooling tunnels or spray cooling systems are common.

- Labeling Machines: Essential for branding, legal requirements, and consumer information. These can apply wrap-around labels, front-and-back labels, or even print information directly onto cans.

- Conveyance Systems: Including belts, elevators, and turners, these systems move cans through various processing stages efficiently and safely, often customized to the layout and flow of the production line.

- Inspection and Quality Control Equipment: To ensure every can meets quality standards, equipment like vision systems for checking fill levels, seam integrity, and label placement, or metal detectors and X-ray machines for contamination checks, are integral.

- End of Line Solutions: Includes case packers that place cans into boxes or trays, palletizers for arranging filled cases onto pallets, and wrapping or strapping machines for securing loads for transport.

Canning line equipment must comply with stringent food safety regulations like HACCP (Hazard Analysis and Critical Control Points), FDA, and other local standards, focusing on hygiene, traceability, and efficiency. Modern canning lines are increasingly automated, incorporating IoT for real-time monitoring and data analytics for continuous improvement. This category not only caters to large industrial setups but also to craft producers looking for scalable solutions, showcasing a blend of durability, efficiency, and adaptability.